Key features

Use for removal of unwanted floodwater and nuisance water from buildings, basements, car parks and garden patios

Maximum flowrate of 180 litres per minute

Made from anti-corrosive and dust-proof materials

Integrated float switch makes pump suitable for use in narrow spaces

Low suction capability down to 2/3mm

Suitable for use with water containing particles up to 5mm

Very low priming and starting level of the pump: 10–15mm (manual operation), 165mm (automatic operation)

Selector for manual or automatic operation

Easy access, through sliding cover, to float switch for cleaning

Motor with thermal overload protection

Excellent cooling of the motor that enables the pump to operate even when it is partially submerged

10 metre mains cable and molded UK plug

1¼ inch top discharge, four-step hose tail supplied

A handy 10-metre length of tough roll-up delivery hose (additional extension lengths available)

A plastic carrying crate for storage and for use if required to filter out leaves and debris

Downloads

Specifications

Model

|

400M |

Operation

|

Automatic (integral float) |

Float Start Height

|

165mm |

Float Stop Height

|

65mm |

Flowrate Max.

|

180 L/min |

Head Max.

|

9m |

Impeller Type

|

Vortex |

Horse Power

|

0.55 HP |

Power

|

0.4 kW |

Voltage

|

230V |

Water Level Min.

|

2/3mm |

Water Temp Max.

|

35°C |

Motor Speed

|

2800 RPM |

Discharge Size

|

1¼ inch |

Free Passage

|

5mm |

Pumped Medium

|

Water & small particles up to 5mm |

Cable Length

|

10m |

Construction

|

Technopolymer |

Weight

|

5.1 Kg |

Dimensions (H x W x L)

|

400mm x 158mm x 225mm |

Technical data

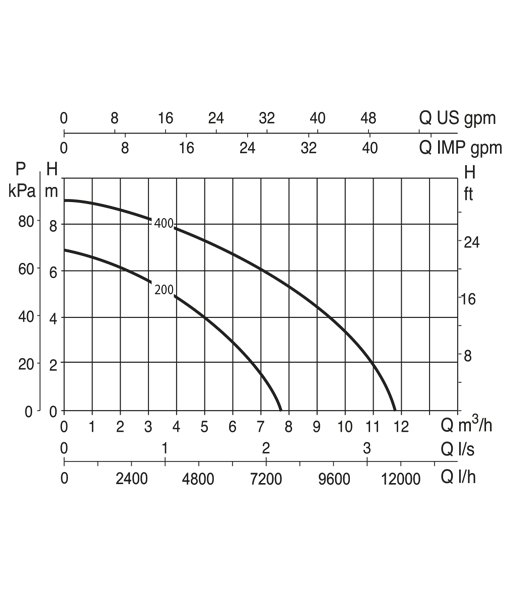

Operating range: from 1 to 10m³/h with head up to 9 metres.

Liquid temperature range: from 0 °C to +35 °C for domestic use

Pumped liquid: dirty water without fibres

Pump priming limit: 10-15 mm in manual operation.

Max. immersion depth: 7 metres

Construction data

Hydro resistant technopolymer pump body, cover, and suction grid

Stainless steel motor, roto shaft, and bolts and screws

Threefold seal with interposed rings with oil pre-chamber

Motor data

Submersible type continuous duty asynchronous motor

Stator enclosed in airtight stainless steel casing, with an outer cover that protects the wiring and the capacitor

Rotor running on permanently lubricated ball bearings, oversized to ensure low noise and durability

Built-in thermal-amperometric protection and permanently connected capacitor